Are you looking for a measurement software that exactly meets your requirements and can be operated without major training? The team of sigma3D develops individual measurement software for you, with which you will reach your goals quickly and efficiently!

What distinguishes us from all other providers in the field of industrial software development is our practice-oriented approach: We bring together expert knowledge in mobile measurement technology with agile development methods for you. Our team consists of developers who themselves have many years of experience in measurement technology and are familiar with the processes of a wide range of industrial sectors. So you can be sure that your measurement software is based on real practical know-how.

We design the user interface of our measurement software to be as simple as possible and guide your personnel through the entire measurement process in compact steps. Even complex measurement processes are no problem and succeed safely and error-free. You can carry out your measurements independently and cost-effectively at any time, instead of having to commission external service providers every time.

Whether classic desktop application or centralized client-server applications with modern web technology: we help you to successfully digitalize your processes with individually developed measurement software!

Your advantages at a glance:

Joint requirements analysis Together we analyze your manufacturing process. We identify problems and clarify what you expect from software, measurement technology and application. Based on this, our team defines the requirements according to which it develops your individual measurement technology software.

Agile software development We develop the measurement software with you in several iterative sprints, after which you can test the first functions again and again. We continuously record your feedback in order to take it into account in the development process. We coordinate the fully developed prototype of your measurement software with your users in a practical test and make final adjustments.

Delivery and long-term support After we have optimized the measurement process on site, we deliver the software to you. This includes training your personnel in one to three days, depending on the measurement program, for smooth application. Of course, we are continuously at your side with support and maintenance for the entire lifetime of your measurement software.

Operators and manufacturers of continuous casting plants are constantly faced with metrological challenges: They must achieve high accuracies for consistently high slab quality. In addition, the downtimes of the plant must remain low in order to avoid costly production interruptions.

We have developed HD LASr, a specialized measurement software for continuous casting plants. It performs 3D measurements of rolls, copper plates and strand guides, performs alignment and provides wear evaluations. The connection of a digital twin of the plant makes it possible to optimally simulate and plan all metrological processes. Thanks to the intuitive user interface, the software measurement can be carried out completely by your own personnel after a short training session.

This enables you to perform completely digital processing, which provides significantly faster and more precise results compared to manual measurement.

The supplier for continuous casting plants SMS Siemag has been relying on the measurement competence of sigma3D for years. Both in the alignment of steel plant components and in the field of industrial software development.

In the past SMS Siemag relied on standard software to align dies and segments with a laser tracker. The problem: The metrology software was so complex that external specialists were required each time for the regular measurement tasks. This cost the company time, money and flexibility.

The solution: The team of sigma3D developed a measurement software including a measurement concept for the steel mill personnel of the end customers. After a short training of the personnel, the plant operators were able to perform all measurement tasks independently. The result: The results became more accurate and reliable, while human and technical sources of error were reduced to a minimum.

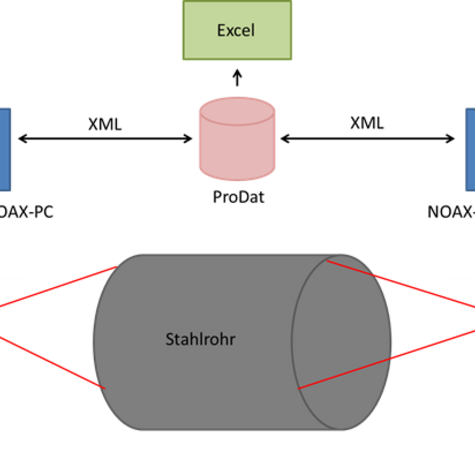

Our team developed the TubeSoft measuring software for quality inspection with laser trackers in the production of large steel tubes: With its help, the factory personnel can precisely control compliance with error tolerances and automatically document them in a connected database. The end result is a detailed results file with all measured values, including the characteristic values defined by the specification file.

Our measurement software guides the users through a clearly defined measurement procedure, which they carry out independently after a short training session. If adjustments to procedures become necessary, settings can be made via password-protected expert access.

We developed this solution for the first time for a specialist manufacturer of large steel pipes based in Germany. For similar applications, we can easily adapt the measuring program to your requirements and further develop it individually.

Wherever industrial robots are used in production, regular robot cell calibration - known as base measurement - is required to ensure consistently high quality results.

We have developed our own measurement program for precisely this special measurement task: RoboCalc, a plug-in for our open source software OpenIndy. The software helps to establish the 6D relationship between robot and fixture in precision applications that are carried out with the help of 3D measuring systems. In addition to the robot base, the tool can be directly co-determined. Our team was able to contribute its extensive measuring experience in automotive and aircraft manufacturing as well as plant manufacturing to the development.

The software is easy and intuitive for the employees to use. The measurement software guides them step-by-step through all processes: measurement, calculation and evaluation - including documentation and data export. The measuring process thus becomes completely digital. The effect: robot bases can be determined significantly faster and more accurately than with standard solutions from manufacturers of measurement software.

For many years, our team has relied on the open source measurement program OpenIndy for automated 3D measurements and calculations.

The open source code allows us to build our development work for you cost-effectively on a proven and future-proof solution. Thanks to numerous plug-ins and self-developed modules, we can flexibly design and further develop your measurement software according to your wishes. All this is manufacturer-independent, license-free and secure - clear advantages for industrial software development.

Our development philosophy includes the use of diverse technologies to optimally fulfill your specific measurement tasks. To achieve this, we combine classic techniques and architectures for industrial software development with modern approaches in order to use the advantages of both worlds. For example, we develop our own services for solution algorithms or sensor controls with smoothly functioning interfaces, such as RPC websocket or REST.

The result: measurement software that, together with automated measurement technology, successfully digitizes your production processes! You benefit from error-free, fast and precise results with consistently high quality.

For more information about the open source measurement program OpenIndy, please visit the software's website.